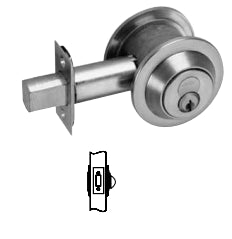

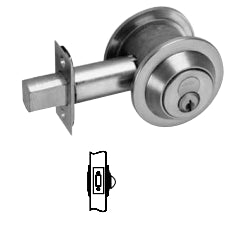

Dorma D861 Cylinder × Blank Plate:

.Dead bolt operated by key one side. Blank plate on other side. .Bolt automatically deadlocks when fully thrown.

Providing increased security, reliability, and durability. DORMA offers a choice of rugged dead bolts to provide an added level of protection. The D800 Series are Grade 1 dead bolts available in both 2-3/8" and 2-3/4" (standard) backsets. The large dead bolt is made from stainless steel for strength and corrosion resistance. A HeavyDuty brass cylinder in a hardened steel housing surrounded by a heavy steel spin ring complete the security package in the door. This is coupled with a solid steel strike for use in a hollow metal frame and an additional reinforcing plate with 3" screws for wood jamb installations. All of these features provide an exceptionally strong and secure dead bolt. All steel parts are zinc dichromate plated.

Recommended Applications .Schools and Universities .Hotels .Apartments .Hospitals and Nursing Homes .Churches .Municipal Buildings .Airports .Retail Complexes .Offices .Warehouses

Technical Details .Hardened steel housing for superior protection against blunt force attack. .Large steel spin ring for protection against attack by wrenching and prying. .(2) 1/4-28 high strength steel mounting screws for protection against prying. .Available in all DORMA SKC keyways in both Small Format Interchangeable Core (SFIC) and standard cylinders. Also available in many Best keyways as well as Schlage C and E, Sargent LA, and many others. Consult factory for additional keyways. .Strike reinforcement with 3" wood screws for wooden jambs provides increased resistance to kick-in attack.

Certification Certified to the requirements of ANSI/BHMA A156.36 Grade 1.

UL/CUL – UL 10C Positive Pressure Listed 3 hour fire rated.

Cylinders and Keying .Unless otherwise specified, cylinders will be provided in DORMA standard keyway with two (2) nickel silver keys. .Optional patented key system available. .Refer to DORMA Price List for full details and options such as master keying, retrofit cylinders and keyways, and small format interchangeable cores.

Warranty For details, refer to DORMA Limited Warranty on our website at go.dorma.com/terms.

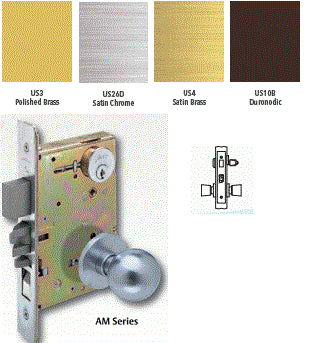

Finishes Brass: 605 (Bright) or 606 (Satin). Bronze: 612 (Satin) or 613 (Dark Oxidized Satin). Nickel: 619 (Satin) Chrome: 625 (Bright) or 626 (Satin).

Antimicrobial Protected Coating Specify AM.

Special Finish Notes ANSI/BHMA A156.18 standards describe 613 Dark Oxidized Satin Bronze finish as a category B finish. B category finishes, “do not match from one alloy or form of material to the next and from one manufacturer to the next.” The 613 finish may vary between manufacturers’ products and models.

In some instances, for customer convenience, the most appropriate BHMA finish symbols are used to indicate similarity of appearance, regardless of base metal or finishing process. Finishes of latches, strikes, cylinders/cores, and visible mounting screws, though similar in appearance, may differ from the finish of the trim. Finish designations in the 600 numbers are the BHMA (Builders Hardware Manufacturers Association) industry standard.

Door Preparation 2-1/8" or 1-1/2" diameter mounting hole.

Security Screws Torx® tamper-resistant screws are available for all exposed screws. Specify TX.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)