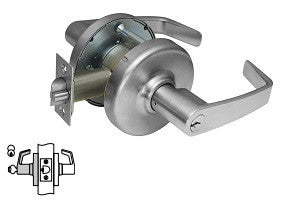

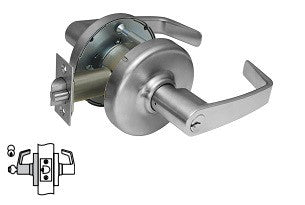

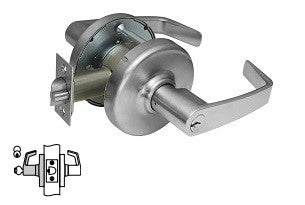

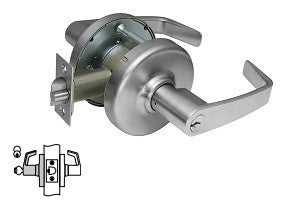

Sargent 10G16 Classroom Security, Apartment, Exit, Privacy Lever. The SARGENT® 10 Line is a heavy duty cylindrical key-in-lever handle lockset exceeds by five times the ANSI 156.2 Series 4000 Grade 1 standards. At over 4 million cycles, the 10 Line beats the competitor by 30%. As for abusive force, this lock endures more than two times the standard without allowing entry. The 10 line trim is designed to conform to national and state fire and handicapped requirements.

- Sargent 10G16 Classroom Security, Apartment, Exit, Privacy Lever-

• Deadlocking latch

• Latch by either lever unless outside lever is locked by key in inside lever

• Key in outside lever retracts latch when outside lever is locked

• Inside lever always operative

• ANSI F88

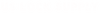

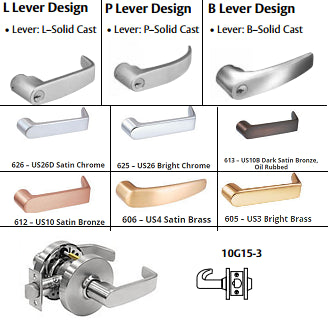

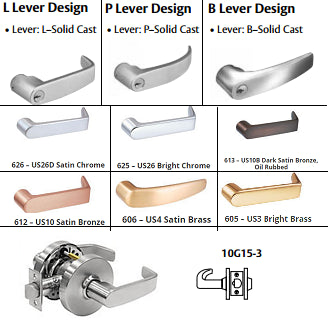

Finishes Come In: 26D,03, 04,10, 10B, 26

Levers Come In: L, B & P

Strength, Durability and Security

- Cycle Test: Exceeds 5 times A156.2 Grade 1 requirements

- Abusive Locked Lever Torque- without entry gained: Exceeds 1.5 times A156.2 Grade 1 requirements

- 7 YEAR LIMITED WARRANTY - no service required to maintain warranty

Convenience

- Installs in 1 minute or less

- Quickly adapts to fit multiple through-bolt positions

- User friendly packaging

- User friendly instruction sheets

- Convenient installation diagram on box

Design

- Solid feel and precise lever action

- Slim rose design available

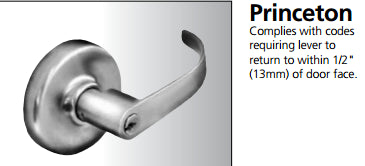

- Decorative Levers — Coastal Series designs – Gulfport and Yarmouth

- Levers are solid one piece cast construction, except “J” lever

Security

- Torx® and spanner screws optional

- Classroom security and multiple locking functions are available

- Vandal resistant, Free Wheeling (FW) trim optional (not available with 70 or 71 functions)

- Security key systems available (Signaturem Keso, BR-XC, XC)

Certification Compliance

- Certified ANSI A156.2 Series 4000-Grade 1

- UL listed to USA and Canadian safety standards. Listed for 3 hour doors (double doors require 41-option) Note: Any retrofit or other field modification to a fire rated opening can potentially impact the fire rating of the opening, and Sargent Manufacturing Company makes no representations or warranties concerning what such impact may be in any specific situation. When retrofitting any portion of an existing fire rated opening, or specifying and installing a new fire-rated opening, please consult with a code specialist or local code official (Authority Having Jurisdiction) to ensure compliance with all applicable codes and ratings.

- Positive Pressure: Meets UL 10C and UBC 7-2 (1997)

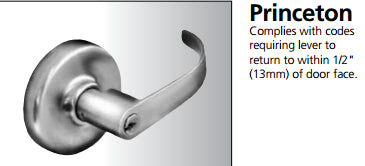

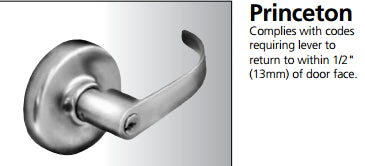

- All levers conform to ADA requirement for barrier-free accessibility

- Levers (L,J & P) conform to California Administrative Code Title 19 and 24

- All individual components of a total door opening are required to comply with each code (Hurricane code)

- Conforms to national & state fire and handicapped requirements

Flexibility

- Fits a variety of door preparations with adaptable through-bolt positioning

- Accommodates retrofit applications with optional 2-3/8", 3-3/4", and 5" backset latches

- 6 ADA lever styles to complement a wide array of design applications

- Levers (B, L, J & P) are non-handed for efficient warehousing and for ease of installation

- 11 Architectural grade finishes

- 21 Functions

- SARGENT uses engineered solutions and flexible manufacturing processes to accommodate special applications