Arrow BM26 Privacy Mortise Lever Lock. Arrow BM Series Lever Mortise Locks are intended for heavy duty use in schools, hospitals and commercial buildings where security, durability and low maintenance are required. They are engineered for strength and performance, and precisely manufactured to exacting standards.

Arrow BM26 Privacy Mortise Lever Lock:

- Latchbolt by knob/lever either side, except when outside is locked by turnpiece inside.

- Operating inside knob/lever, closing door, or with outside emergency release unlocks outside.

Handing – Handed; field reversible. The lockset can be re-handed without disassembling the lock case.

- Door Thickness – 1-3/4" (4mm) standard.

- Backset – 2-3/4" (70mm).

- Lockcase – Heavy gauge steel, with zinc dichromate finish for corrosion resistance. 5-7/8" (149mm) x 4" (102mm) x 15/16" (24mm).

- Armored Front – Heavy gauge steel, 8" (203 mm) x 1-1/4" (32mm) x 3/32" (2mm). Accommodates flat doors and doors beveled 1/8" (3mm) in 2" (51mm).

- Faceplate – Wrought brass, bronze or stainless steel. Attached by machine screws to lockcase front.

- Latchbolt – Stainless steel, 2 piece mechanical with anti-friction insert. 5/8" (16mm) x 1" (25mm) x 3/4" (19mm) throw.

- Auxiliary Latchbolt – 9/16" (14mm) effective throw and 3/8" (10mm) effective auxiliary latch deadlocking.

- Deadbolt – One-piece stainless steel, 19/32" (15mm) x 1 1/4" (32mm) x 1" (25mm) throw.

- Hub – Knob: nickel steel, 5/16" (8mm) and 9/32". Lever: nickel steel, 5/16" (8mm).

- Spacing – Center to center, hub to cylinder: 3-5/8" (92mm). Center to center, hub to turnpiece 2-7/16" (62 mm)

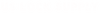

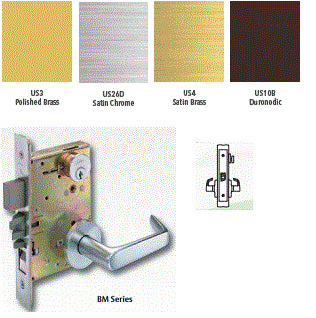

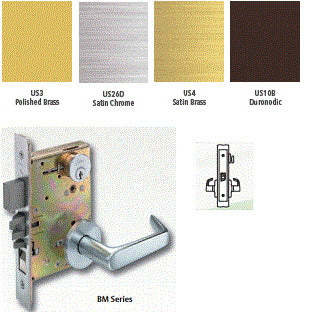

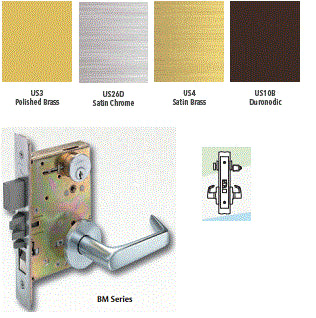

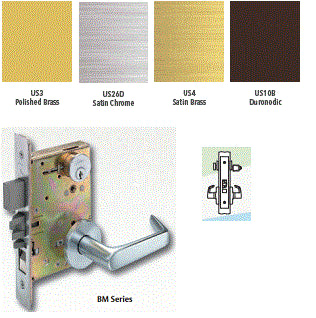

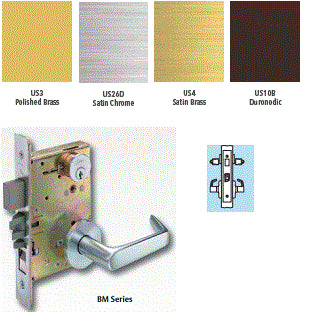

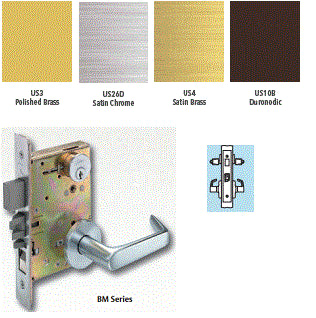

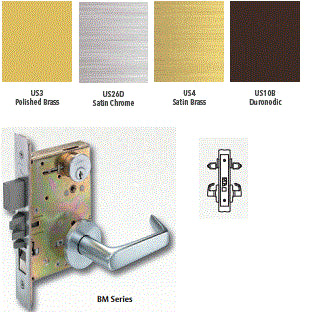

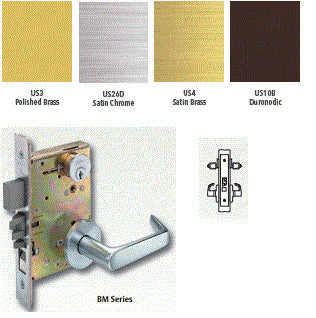

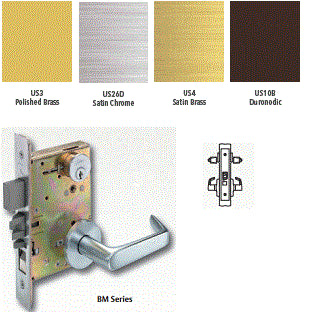

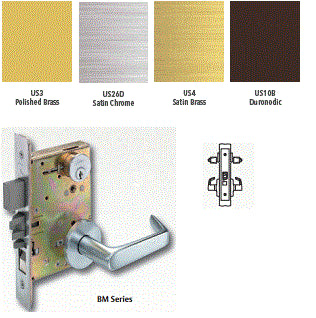

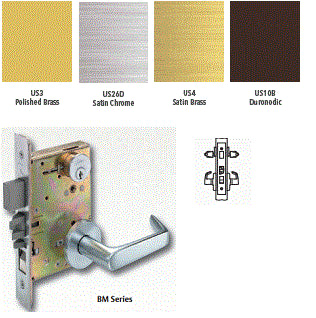

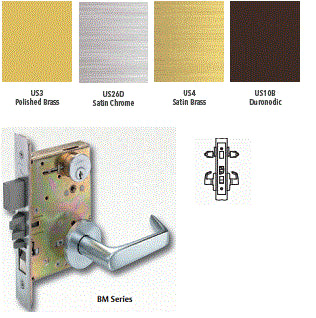

- Finishes: 26D, 10B, 04, 03.

- Lever Trims: BRL, HSL, BRH, HSH, JL, VL, XL, JH, VH, XH.

Certification/Compliance:

ANSI Meets A156.13 Series 1000, Operational Grade 1.

Federal Meets FF-H-106C, Series 86 and 87.

UL/ULC Positive Pressure All locks listed for A Label and lesser class doors, 4" (122cm) x 10" (305cm) single or 8" (244cm) x 10" (305cm) pair. Letter F and UL symbol on armored front indicate listing. California State Reference Code All levers with returns comply; levers return to within 1/2" (13mm) of door face.

Advantages: • Easily reversible, enabling the user to reverse hands without disassembling lock case. • Meets or exceeds ANSI operational Grade 1 requirements. • Throughbolted trim designs for proper alignment and increased security. • Many trim designs to complement Arrow cylindrical locks and exit device trims. • Keyed into new or existing Arrow or competitive master key systems. * Note: Not all trim designs available in all finishes.